I-China 6 Axis 1800mm Arm ifinyelela ku-Automatic Steel MIG Welding Robotic Arm

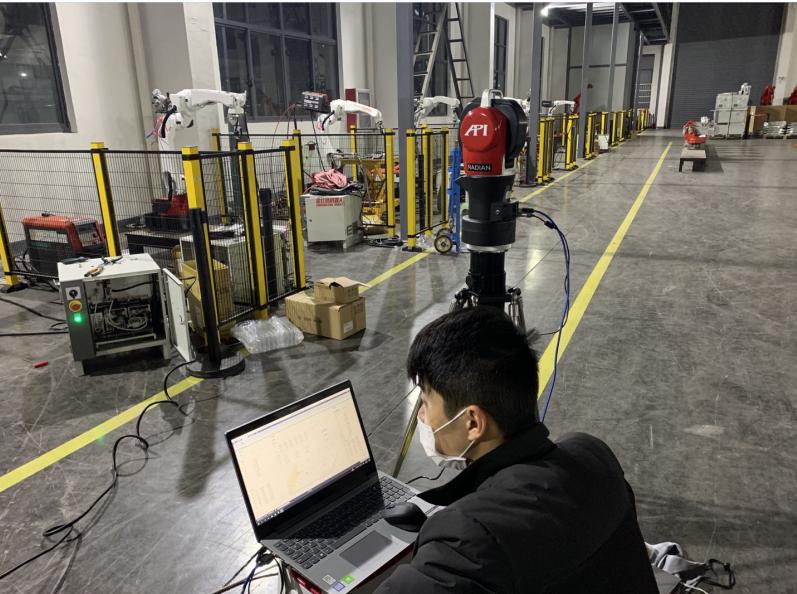

I-LASER CALIBRATION TEST UKUNEMBA KOKUBUYISWA KOKUFA

I-JHY isebenzisa indlela yokulinganisa i-laser ukuze ihlole ukunemba kokuma okuphindaphindiwe kwerobhothi.Ngemva kokuhlolwa okuningi, ukunemba okuphindaphindiwe kokuma kwerobhothi kuphezulu kakhulu kuno-±0.08mm.

SEBENZISA IBRANDE EZISEPHEZULU IZISEKELO ZOMNAKA

Izesekeli eziyinhloko zamarobhothi njenge-servo motor, i-RV reducer, i-harmonic reducer, i-servo drive njalo njalo zonke zisebenzisa ama-brand ase-China aphezulu, ahlolwe ngokusetshenziswa kwethu isikhathi eside ukuze kuqinisekiswe ukuthi afanele irobhothi lethu.

UKUNIKELA OKULULA

Isondlo silula, Ngokomhlahlandlela wesondlo esinikezwa yithi amakhasimende ngokwawo angasebenza kalula.

NGEMVA KWESIQINISEKISO SOKUDAYISWA

Ikhasimende ngalinye lineqembu lalo lesevisi yangemuva kokuthengisa.Uma udinga noma yiluphi usizo ngemva kokuthengisa, Pls buza noma nini.Onjiniyela bethu abangochwepheshe bazoyixazulula ngesikhathi esifushane.Iphuzu liwukuthi konke kumahhala.

| Ireferensi yemingcele yokushisela yensimbi emnene nensimbi ye-alloy ephansi | |||||||||

| uhlobo | ipuleti | Ububanzi bentambo | igebe lempande | welding current | welding voltage | isivinini sokushisela | Thinta ithiphu-workpiece ibanga | Ukugeleza kwegesi | I-angle yokushisela |

| Ukushisela izinqe okumise okwe-T | 1.0 | 0.8 | 2.5-3 | 70; 80 | 17-18 | 8; 10 | 10 | 10-15 | 45° |

| 1.2 | 1.0 | 3 - 3.5 | 85; 90 | 18-19 | 8; 10 | 10 | 10-15 | 45° | |

| 1.6 | 1.0,1.2 | 3 - 3.5 | 100-110 | 18-19.5 | 8; 10 | 10 | 10-15 | 45° | |

| 2.0 | 1.0,1.2 | 3 - 3.5 | 115-125 | 19.5-20 | 8; 10 | 10 | 10-15 | 45° | |

| 2.3 | 1.0,1.2 | 3 - 3.5 | 130-140 | 19.5-21 | 8; 10 | 10 | 10-15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5-4 | 150-170 | 21-22 | 7.5-8 | 15 | 15 - 20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5-5 | 180 - 220 | 21-23 | 6.5-7.5 | 15 | 15 - 20 | 45° | |

| 1.2 | 5 - 5.5 | 200 - 250 | 24-26 | 6.5-8 | 10-15 | 10 - 20 | 45° | ||

| 6 | 1.2 | 5 - 5.5 | 230 - 260 | 25-27 | 6.5-7.5 | 20 | 15 - 20 | 45° | |

| 6 | 220-250 | 25-27 | 5.5-7.5 | 13-18 | 10 - 20 | 45° | |||

| 4 - 4.5 | 270-300 | 28-31 | 10 - 11.5 | 13-18 | 10 - 20 | 45° | |||

| 8,9 | 1.2,1.6 | 6; 7 | 270-380 | 29-35 | 6.5-7.5 | 25 | 20 - 25 | 50° | |

| 8 | 1.2 | 5; 6 | 270-300 | 28-31 | 9; 10 | 13-18 | 10 - 20 | 45° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 - 5.5 | 15 - 20 | 10 - 20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30 - 34 | 5 - 5.5 | 15 - 20 | 10 - 20 | 50° | ||

| 12 | 1.2,1.6 | 7; 8 | 270-380 | 27-35 | 4.5-6.5 | 20 - 25 | 20 - 25 | 50° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 - 5.5 | 15 - 20 | 10 - 20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30 - 34 | 5; 6 | 15 - 20 | 10 - 20 | 50° | ||

Qaphela:

1. Ukushisela kwe-MIG kusebenzisa igesi engasebenzi, ikakhulukazi esetshenziselwa ukushisela i-aluminium nama-alloys ayo, ithusi nama-alloys ayo, i-titanium nama-alloys ayo, kanye nensimbi engagqwali nensimbi engashisi.Ukushisela kwe-MAG kanye ne-CO2 yegesi evikelekile isetshenziselwa ikakhulukazi ukushisela i-carbon steel kanye ne-low alloy high power steel.

2. Okuqukethwe okungenhla okokubhekisela kuphela, futhi kungcono kakhulu ukuthola amapharamitha wenqubo yokushisela ngokuqinisekisa kokuhlola.Amadayimitha ocingo angenhla asekelwe kumamodeli wangempela.